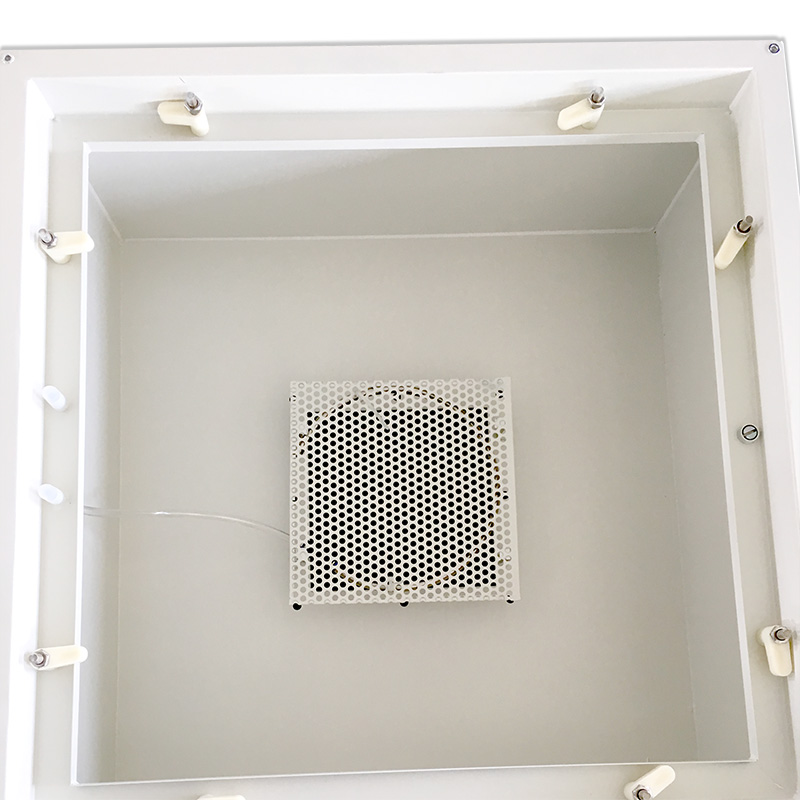

HEPA BOX

HEPA box, also called filter housing, is the ideal terminal filter device for air conditioning systems requiring purification to meet the cleanroom level. It can provide the desired static pressure before airing the HEPA, thus making the air outlet uniformity. We are extremely focused on the details of our products, making our HEPA box superior to the most products on the market.

We use one‐piece bending design together with robot welding joint to ensure excellent leak‐proof performance. Representative filter from each batch type and production run are subjected to a complete test flow evaluation to determine efficiency, pressure drop and dust holding capacity. Airflow pipe can be connected directly through top access or side access with either circular or rectangular inlet.

We use one‐piece bending design together with robot welding joint to ensure excellent leak‐proof performance. Representative filter from each batch type and production run are subjected to a complete test flow evaluation to determine efficiency, pressure drop and dust holding capacity. Airflow pipe can be connected directly through top access or side access with either circular or rectangular inlet.

OPTIONS

- Match gasket HEPA

- Match gel seal HEPA

- Top connected

- Side connected

FRAMES

- Steel Powder Coated

- Aluminum

- SS 304

GRILLE

- Perforated

- Louvers

- Swirl

| Model | Hepa Size | Box Size | Flange Size | Height Of Box | Hole Size |

|

HB 500

|

410×410×93

|

460×460×250

|

200×200

|

500

|

470×470

|

|

HB 1000

|

550×550×93

|

600×600×250

|

320×200

|

1000

|

610×610

|

|

HB 1500

|

650×650×93

|

700×700×250

|

320×250

|

1500

|

710×710

|

FFU Fan-Filter Unit

FFU is the simplest purifying equipment consisting of fan and HEPA filter, and the most basic type in air purifying equipment. Due to the one‐to‐one correspondence between HEPA filter and fan, a negative pressure area is formed outside the unit case to enable negative pressure sealing function. FFU may be used separately or in combination to achieve higher cleanness easily. FFU makes the design of clean room easier and more reliable. FFU, characterized by low energy consumption, low noise and low operating cost, is widely applied to unidirectional flow and turbulent flow clean room and working station, unidirectional flow hood, clean booth and local purifying equipment in micro‐electronics, electronics, optics, bioengineering and other industries.

OPTIONS

- DOP Test Port

RAMES

- Zinc Aluminized Sheet

- SS

FAN

- DC

- AC

SPEED CONTROL

- Five speed control

- Stepless speed

| Model | Overall Size | Air Volume | Initial Resistance | Noise | Power |

|

FFU10-11757

|

1170×570×350

|

1000/0.45

|

100 (Efficiency (H14) 0.3μm ≥99.995%)/ 160 (Efficiency (U15)0.1μm ≥99.9995%) |

57

|

0.18

|

|

FFU15-11787

|

1170×870×350

|

1500/0.45

|

60

|

0.25

|

|

|

FFU20-117117

|

1170×1170×350

|

2000/0.45

|

63

|

0.37 |

Class A Laminar Airflow (LAF)

Class A Laminar Airflow (LAF), also called Unidirectional Flow Hood (UFH) is a type of air purifying equipment providing Class A unidirectional flow and thus creating highly clean environment.

LAF is used for the protection of the filling/packaging operations of products that are sensitive to contamination, may be used separately or in combination. It can be designed to have independent air return system, or to connect with current duct.

LAF is used for the protection of the filling/packaging operations of products that are sensitive to contamination, may be used separately or in combination. It can be designed to have independent air return system, or to connect with current duct.

MAIN FEATURES

- Combination and modularization

- Less investment,quicker effects,easier installation, lower energy consumption

- Double negative pressure

- Flexible way to install

- High quality HEPA filter,high cleanness, ensure sterility

- Rich control module,meet different requirements

OPTIONS

- Hanging mount: hoisting or ceiling

- Floor stand

- Air supply from air duct

- Air supply by built-in blower

- Economic AC blower or higher performance EC blower are available

- Blowers can be controlled individually or in groups

| Model | Overall size WxDxH |

Working area size W1xD1 | Upstream rated air velocity (m/s) | Working area clean class (grade) | Noise (dB) | Illumination (Lux) | Power (kW) |

| UFH-1260 | 1200x600x600 | 1200x600 | 0.45±20% | A | 65 | 300 | 0.3 |

| UFH-1010 | 1000x1000x600 | 1000x1000 | 0.45 | ||||

| UFH-1212 | 1200x1200x600 | 1200x1200 | 0.6 | ||||

| UFH-2010 | 2000x1000x600 | 2000x1000 | 0.9 | ||||

| UFH-2012 | 2000x1200x600 | 2000x1200 | 1.2 | ||||

| UFH-2020 | 2000x2000x600 | 2000x2000 | 1.8 |

Pass Box

Pass box include dynamic pass box and static pass box.

It is used for the transfer of materials/ products between two areas of different classes.

The doors are interlocked by magnetic device and provide a buffer area for transferring material/ product through the room with different classes.

Provided with UV germicidal lamp, or ozone generator steriIization system based on the user's demand.

It is used for the transfer of materials/ products between two areas of different classes.

The doors are interlocked by magnetic device and provide a buffer area for transferring material/ product through the room with different classes.

Provided with UV germicidal lamp, or ozone generator steriIization system based on the user's demand.

OPTIONS

- Electrical or Mechanical interlocking system.

- Dynamic Type

- UV Lamp Sterilization

- Easy-to-install by Wall mounted Floor mounted or Pit mounted

- Customized Size and Function Design

| Model | Overall size WxDxH |

Working area size W1xD1xH1 | Clean class | Upstream rated air velocity (m/s) | UV sterilizer (W) | Ozone Concentration (ppm) | Noise (dB) | Power (kW) |

| PB4-50 | 700x560x1000 | 500x500x500 | A | 0.45±20% | 8 | 20~50 | 65 | 0.15 |

| PB5-60 | 800x660x1100 | 600x600x600 | 15 | 0.15 | ||||

| PB6-70 | 1000x800x1300 | 800x800x800 | 15 | 0.15 |

Transfer Hatch

Transfer Hatch is used for transferring materials. The hatch are alI made of SS 304 with a surface finish of Ra< 0.8 µm There will be climbing ramp and rollers made of SS304 at the bottom of the hatch for convenience of material transfer.

The doors are interlocked by magnetic device and provide a buffer area for transferring material/ product through the room with different classes. Provided with UV germicidal lamp, or ozone generator sterilization system based on the user's demand.

The doors are interlocked by magnetic device and provide a buffer area for transferring material/ product through the room with different classes. Provided with UV germicidal lamp, or ozone generator sterilization system based on the user's demand.

OPTIONS

- Electrical or Mechanical interlocking system

- Air Shower Type

- UV Lamp Sterilization

- Easy-to-install by Floor mounted or Pit mounted

- Customized Size and Function Design

| Model | Overall size WxDxH |

Working area size W1xD1xH1 | Clean class | Upstream rated air velocity (m/s) | UV sterilizer (W) | Ozone Concentration (ppm) | Noise (dB) | Power (kW) |

| HT4-50 | 700x560x1000 | 500x500x500 | A | 0.45±20% | 8 | 20~50 | 65 | 0.15 |

| HT5-60 | 800x660x1100 | 600x600x600 | 15 | 0.15 | ||||

| HT6-70 | 1000x800x1300 | 800x800x800 | 15 | 0.15 |

HP Aseptic Transfer Chamber

VHP Aseptic Transfer Chamber integrates a vaporized hydrogen peroxide (VHP) generator to provide VHP gas to the inside of the pass box for biological decontamination treatment on the outer surface of the material to prevent the material from entering A from non-grade areas or low-grade clean areas, B-level critical areas bringing pollution.

It can be used for all kinds of clean and dry items that need to be delivered in aseptic production, including packaging materials, instruments, raw and auxiliary materials, accessories, environmental monitoring equipment, etc. that enter the A and B key areas.

It can be used for all kinds of clean and dry items that need to be delivered in aseptic production, including packaging materials, instruments, raw and auxiliary materials, accessories, environmental monitoring equipment, etc. that enter the A and B key areas.

MAIN FEATURES

- Inner chamber and tank with radius corners for better cleanability.

- Tempering glass in doors provides a clear view of internal chamber.

- Pneumatically interlocked doors ensure only one door can be open at one time when operating.

- The main body of the transfer chamber is constructed of SS304 for exterior and SS316 for interior.

- Two operation modes:manual or automatic control by using Siemens PLC control.

- H14 grade HEPA filter

- Environmental friendly and leaving no harmful residues and Iingeri ng door.

- Low temperature decontamination.

- All detail info can be recorded,comply with GMP,USP standard.

- Fault alarm function

- Bacteria killing rate can reach 6 log when take Bacillus stearothermophilus and Bacillus subtilis black variant as challenge

OPTIONS

- Low temperature (18-26 °C) compatible with Biologics

- Faster process time ≤ 50 min for 3m3 chamber

- Use 7% Analytical Reagent

| Model | Overall size WxDxH | Working area size W1xD1xH1 | Air velocity (m/s) | Volume (m3) | Power Capacity | Sterilant | Sterilization cycle |

| VHP-60 | 1200x700x1950 | 600x600x600 | 0.36-0.54 | 0.25 | AC220V /50Hz /2500W |

30% analytical grade hydrogen peroxide solution |

>1 hour |

| VHP-70 | 1300x800x2050 | 700x700x700 | 0.4 | ||||

| VHP-80 | 1400x900x2150 | 800x800x800 | 1 | ||||

| VHP-100 | 1600x1100x2000 | 1000x1000x1000 | 1.5 | ||||

| VHP-120 | 1800x1400x2550 | 1200x1300x1650 | 2.5 |

Sampling / Dispensing / Weighing Booth

Sampling booth is used for the sampling, dosing or weighing of the chemical components, sampling antibiotics, hormones, cytostatics, etc either powders or Iiquids that make up the finished products.

The sampling booth allow to obtain delimited environment area of clean and sterile air class ISO 5, through a unidirectional and descendant air filtered flow with lower pressure in the operation area. Assures a slight depression and, therefore, an isolating from the surrounding area.

The possibility of cross contamination with other products is avoided.

The sampling booth allow to obtain delimited environment area of clean and sterile air class ISO 5, through a unidirectional and descendant air filtered flow with lower pressure in the operation area. Assures a slight depression and, therefore, an isolating from the surrounding area.

The possibility of cross contamination with other products is avoided.

MAIN FEATURES

- Round corner design for the working area, dust free, easy to clean

- Air curtain isolated, convenient operation

- Excellent unidirectional flow pattern, no dust dispersion

- Differential Pressure

- The Internal components are all installed in the SS304 cabinet and will never accumulate any dust after long time use

OPTIONS

- Material SS304 / 316

- Three stages filtration: G4, F8, H14

- Exhaust Filter with suitable size

- Air Flow Rate:0.45±0.1 m/sec

- Complete weighing management system with function of scanning code, weighing and labeling

- Audit trail comply with 21 CFR Part 11

| Model | Overall size WxDxH | Working area size W1xD1 | Upstream rated air velocity (m/s) | Working area clean class (grade) | Noise (dB) | Illumination (Lux) | Power (kW) |

| SB12-120 | 1300x1200x2570 | 1200x600x2000 | 0.45±20% | A | 75 | 300 | 0.3 |

| SB16-100 | 1600x1800x2570 | 1500x1200x2000 | 0.45 | ||||

| SB24-120 | 2100x2700x2570 | 2000x2000x2000 | 0.6 | ||||

| SB32-200 | 3100x2700x2570 | 3000x2000x2000 | 0.9 | ||||

| SB48-120 | 4100x3200x2570 | 4000x2500x2000 | 1.2 |

Transfer Trolley / Clean Operation Bench

Transfer trolley is used for the storage and the transfer of products that are sensitive to contamination, between two class A areas, and through a class C area.

A laminar air flow class ISO 5 is maintaining a positive pressure within the transfer trolley avoiding any cross contamination.

The transfer trolleys are equipped with a system of electrical plug / embarked battery, that maintain the laminar flow conditions in the transfer trolley at all times.

A laminar air flow class ISO 5 is maintaining a positive pressure within the transfer trolley avoiding any cross contamination.

The transfer trolleys are equipped with a system of electrical plug / embarked battery, that maintain the laminar flow conditions in the transfer trolley at all times.

| Model | Overall size WxDxH | Working area size W1xD1 | Upstream rated air velocity (m/s) | Working area clean class (grade) | Noise (dB) | Illumination (Lux) | Power (kW) |

| TT8-120 | 800x650x1800 | 720x600x750 | 0.45±20% | A | 65 | 300 | 0.18 |

| TT10-100 | 1000x650x1800 | 920x600x750 | 0.18 | ||||

| TT15-120 | 1200x750x1800 | 1120x700x750 | 0.25 | ||||

| TT19-200 | 1400x850x1800 | 1320x800x750 | 0.36 |

The clean operation bench is used for sampling, dispensing and weighing of small / large quantities of toxic products protecting the operator from any contamination, confining the sampling / weighing / dispensing operation.

The clean operation bench is autonomous and easily moveable.

Available with PLC+ touch LCD screen or push button panel.

The clean operation bench is autonomous and easily moveable.

Available with PLC+ touch LCD screen or push button panel.

| Model | Overall size WxDxH | Working area size W1xD1xH1 | Clean class | Upstream rated air velocity (m/s) | Noise (dB) | HEPA Size WxDxHxNos |

| CB10V-97.72D | 970x720x1600 | 810x700x500 | 100 (A) | 0.45±20% | 65 | 760x610x70x1 |

| CB15V-145.72D | 1450x720x1600 | 1290x700x500 | 610x610x70x2 | |||

| CB 10H-97.82C | 970x825x1500 | 810x650x600 | 760x610x70x1 | |||

| CB15H-140.82C | 1400x825x1500 | 1290x650x650 | 610x610x70x2 |

Air Shower

Air Showers are enclosed chamber placed at the entry and exit points of a cleanroom or other controlled environment.

Using high-velocity jets of air and HEPA or ULPA air filter systems, cleanroom air showers remove loose contaminants from people and products before they enter the cleanroom, reducing or eliminating product defects for increased yields.

Contaminants are easily transported by people and objects and a simple spec of lint or debris could cause issues in some cleanroom environments.

Therefore, cleanroom air showers have become a vital component in maintaining the cleanliness of cleanrooms and other clean-critical environments.

Using high-velocity jets of air and HEPA or ULPA air filter systems, cleanroom air showers remove loose contaminants from people and products before they enter the cleanroom, reducing or eliminating product defects for increased yields.

Contaminants are easily transported by people and objects and a simple spec of lint or debris could cause issues in some cleanroom environments.

Therefore, cleanroom air showers have become a vital component in maintaining the cleanliness of cleanrooms and other clean-critical environments.

FRAME

- SS304

- SS316

- Steel powder coated

AIR SPEED

- z25m/s

AIR SHOWER TIME

- 0-99s adjustable

| Model | Overall size WxDxH | Working area size W1xD1xH1 | Nozzles quantity | Power supply | Power Consumption (kW) | HEPA Size WxDxHxNos |

| AS11-120 | 1200x1000x2150 | 800x900x2000 | 6 | AC/3Ph/ 380V/50Hz | 0.75 | 610x610x69x1 |

| AS12-130 | 1300x1000x2150 | 800x900x2000 | 12 | 1.12 | 610x610x69x2 | |

| AS22-130 | 1300x1300x2150 | 800x1200x2000 | 16 | 2.2 | 915x610x69x2 |

Fogging Shower

Mist Shower / Fogging Shower is now widely used in industries for decontamination from the cloths of the user. A mixture of air and water is spray on the cloths of the users. Comes with the microprocessor or PLC unit to control the whole process.

Our versatile mist shower are quite adept at controlling the level of contamination for particle sensitive processes such as pharmaceutical drug testing and for research applications involving molecular biology and biochemical experiments, cell and tissue culture experiments etc.

The entire mist shower assembly is HEPA / ULPA filtered, pre-wired and tested, ready to use with a simple plug-in, therefore providing an unmatched ease of operation.

Our versatile mist shower are quite adept at controlling the level of contamination for particle sensitive processes such as pharmaceutical drug testing and for research applications involving molecular biology and biochemical experiments, cell and tissue culture experiments etc.

The entire mist shower assembly is HEPA / ULPA filtered, pre-wired and tested, ready to use with a simple plug-in, therefore providing an unmatched ease of operation.

FRAME

- SS304

- SS316

AIR SPEED

- z25m/s

AIR SHOWER TIME

- 0-99s adjustable

DOOR MOC

- SS304/316

| Model | Overall size WxDxH | Working area size W1xD1xH1 | Nozzles quantity | Power supply | Power Consumption (kW) |

| MS11-120 | 1200x1000x2150 | 800x900x2000 | 6 | AC/3Ph/ 380V/50Hz | 0.75 |

| MS12-130 | 1300x1000x2150 | 800x900x2000 | 12 | 1.12 | |

| MS22-130 | 1300x1300x2150 | 800x1200x2000 | 16 | 2.2 |

Biological Safety Cabinet - Class II A2

Class II A2 Biological safety cabinet (BSC) is a box-type air purification negative pressure safety device that can prevent some dangerous or unknown biological particles from escaping aerosols during experimental operation. It is widely used in scientific research, teaching, clinical inspection and production in the fields of microbiology, biomedicine, genetic engineering, biological products, etc. It is the most basic safety protection equipment in the first-level protective barrier of laboratory biosafety.

Vertical laminar negative pressure model, 70% of the airflow is filtered and recycled, and 30% of the airflow can be discharged into the room or connected to the exhaust system after being filtered. Safety interlock system for sterilization systems.

Large-screen LCD display, real-time monitoring of running status, password manage ment can be set to prevent misoperation, display the life of the filter and the running time of the blower and UV lamp. Each biological safety cabinet is factory tested for safety and product performance in accordance with international standards.

Vertical laminar negative pressure model, 70% of the airflow is filtered and recycled, and 30% of the airflow can be discharged into the room or connected to the exhaust system after being filtered. Safety interlock system for sterilization systems.

Large-screen LCD display, real-time monitoring of running status, password manage ment can be set to prevent misoperation, display the life of the filter and the running time of the blower and UV lamp. Each biological safety cabinet is factory tested for safety and product performance in accordance with international standards.

| Parameter | Model |

||

| YT-S/ F-1300-A2 | YT-S/F-1600-A2 | YT-S/F-1800-A2 | |

| Dimensions WxDxH (mm) | 1300x795x2000 | 1600x795x2000 | 1800x795x2000 |

| Work area size WxDxH (mm) | 1100x630x630 | 1400x630x630 | 1600x630x630 |

| Front window operating opening height (mm) | 150-200 | ||

| Material | Working area SS316L External SS304 or Cold-rolled steel with anti-bacteria power coating |

||

| Airflow Mode (External Exhaust Flow Proportion) | Vertical downflow, 70% air re-circulation, 30% air exhaust | ||

| Blower model and quantity | D4E220, 1 unit | D4E225, 1 unit | D4E225, 1 unit |

| Specification and quantity of air velocity sensor | YGM215, 2 pcs | ||

| HEPA filter model | U15 | ||

| Exhaust filter size and quantity | 600x400x100, 1 piece | 800x400x100, 1 piece | 1000x400x100, 1 piece |

| Air supply filter size and quantity | 1105 x 465 x 70, 1 piece | 1405 x 465 x 70, 1 piece | 1605 x 465 x 70,1 piece |

| UV Lamp Specifications and Quantity | T5 -20W, 1 pc | T6- 30W, 1 pc | T6-40W, 1 pc |

| Lighting Specifications and Quantity | LED-8W, 1pc | LED-12W, 1pc | LED-14W, 1pc |

Biological Safety Cabinet - Class II B2

Class II B2 Biological safety cabinet (BSC) The working principle is mainly to suck the air in the cabinet to the outside, keep the negative pressure in the cabinet, and protect the staff through vertical airflow the outside air is filtered by HEPA and enters the safety cabinet to avoid pollution. The air in the cabinet also needs to be filtered by HEPA filter and then discharged into the atmosphere to protect the environment. Vertical laminar negative pressure model,100% of the airflow can be discharged into the room or connected to the exhaust system after being filtered. Safety interlock system for sterilization systems.

Large-screen LCD display, real-time monitoring of running status, password management can be set to prevent misoperation, display the life of the filter and the running time of the blower and UV lamp. Each biological safety cabinet is factory tested for safety and product performance in accordance with international standards.

Large-screen LCD display, real-time monitoring of running status, password management can be set to prevent misoperation, display the life of the filter and the running time of the blower and UV lamp. Each biological safety cabinet is factory tested for safety and product performance in accordance with international standards.

| Parameter | Model |

||

| YT-S/ F-1300-B2 | YT-S/F-1600-B2 | YT-S/F-1800-B2 | |

| Dimensions WxDxH (mm) | 1300x795x2000 | 1600x795x2000 | 1800x795x2000 |

| Work area size WxDxH (mm) | 1100x630x630 | 1400x630x630 | 1600x630x630 |

| Front window operating opening height (mm) | 150-200 | ||

| Material | Working area SS316L External SS304 or Cold-rolled steel with anti-bacteria power coating |

||

| Airflow Mode (External Exhaust Flow Proportion) | Vertical downflow, 100% air exhaust | ||

| Blower model and quantity | D4E220, 1 unit | D4E225, 1 unit | D4E225, 1 unit |

| Specification and quantity of air velocity sensor | YGM215, 2 pcs | ||

| HEPA filter model | U15 | ||

| Exhaust filter size and quantity | 600x400x100, 1 piece | 800x400x100, 1 piece | 1000x400x100, 1 piece |

| Air supply filter size and quantity | 1105 x 465 x 70, 1 piece | 1405 x 465 x 70, 1 piece | 1605 x 465 x 70,1 piece |

| UV Lamp Specifications and Quantity | T5 -20W, 1 pc | T6- 30W, 1 pc | T6-40W, 1 pc |

| Lighting Specifications and Quantity | LED-8W, 1pc | LED-12W, 1pc | LED-14W, 1pc |

Water Shower Cabin

Water shower cabin is a Biosafety protection system. The whole is welded by AISl304 stainless steel. The interior adopts laser continuous full welding technique. The entrance and exit use biosafety airtight doors.The internal negative pressure working environment effectively prevents the leakage of pollutants.The equipment adopts the design process of top-row and bottom-feeding to reduce internal fog and improve personnel comfort. The top air supply has a built-in filter device to ensure the cleanliness of the fresh air. The top exhaust filtration system has a built-in high-efficiency filter and is equipped with disinfection and scanning leak detection functions to effectively ensure that pollutants do not leak. The top adopts stainless steel shower head, and the water temperature is automatically controlled. Built-in LED lighting and stripper. This product is suitable for P3/P4 biological laboratory or high-demand pharmaceutical workshop disinfection and sterilization key areas.